BPTM Tubing

|

| BPTM 15/6-A/U (50 ft roll) |

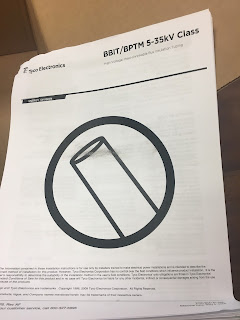

Raychem / TE Connectivity's medium wall, heat shrinkable BPTM tubing provides insulation enhancement and protection against flash over and accidentally induced discharge.

Particularly useful in confined spaces, BPTM tubing can be used on both circular and rectangular copper or aluminum busbars. On application of heat, the BPTM tubing shrinks snugly over the busbar profile ensuring that the required minimum wall thickness is obtained. Raychem BPTM tubing can be installed easily during large scale production using an oven or in the field using a gas torch or hot air. Raychem BPTM tubing is manufactured from a non-halogen based polymer which has excellent performance in high voltage environments and greatly reduces the noxious and corrosive effects in fire situations.

The use of TE's Raychem BPTM tubing allows equipment designers the freedom to reduce air spacing between busbars, such as in the manufacture of switchgear cabinets where space is at a premium. Raychem BPTM tubing provides flashover protection up to 25kV.

Key Features:

- Exceptional insulation and long term reliability even at high continuous operating temperatures.

- Extremely durable, resists damage from solvents, ultraviolet light, weathering, mechanical impact and general wear and tear.

- Suitable for indoor and outdoor use.

- Excellent anti-tracking properties.

- Can be stored indefinitely at temperatures up to 50C without loss of performance.

BPTM is available in the following sizes:

- BPTM 15/6

- BPTM 30/12

- BPTM 50/20

- BPTM 75/30

- BPTM 100/40

- BPTM 120/50

- BPTM 175/70

- BPTM 205/110

- BPTM 235/130