Raychem CST - Cold Shrink Termination

Why is the Raychem CST better than some of the other competitive options in the marketplace?

One advantage is that

it has a large misplacement range. Typically, when a termination is

misplaced, it is towards the lug end. We created our stress cone with a

very large Faraday cage region to account for this. The customer has

well over 1” of area they can land the semi-con cutback of the cable and

still have effective stress control. We don’t advocate for sloppy

workmanship but we do want to try and give the installers as much help

as we can.

In

addition, we developed a new EZ-Pull holdout which not only has a much

lower overall pull force, but is very consistent in the force. This

prevents the “jerking” that can happen with other holdouts. It is hard

to put how much better the holdout feels into words since it is a very

“touch” related thing. Installers are raving about this improved feature.

- Our CST uses a geometric stress control with void-filling mastic rather than a different option

- The CST indoor term also has mini-sheds that improve creepage distance, but still allow for installation in tight-fitting areas.

- Lower cost than the alternatives in the market.

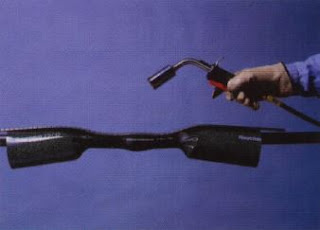

TE Connectivity's Raychem CST cold shrink terminations are the one piece solution for high performance in cold applied terminations for polymeric cables up to 28kV. CST offers a reliable, fast and easy to install system to ensure trouble free service. All components are pre-expanded on an easy to remove spiral hold out allowing installation in compact environments on prepared cable.

The silicone body is specially formulated for excellent tracking and erosion resistance. The extra long stress cone aids in correct positioning and integrated void-filling mastic eliminates the need for silicon grease. Sealing mastic for the lug end is built into the expanded termination eliminating the need for additional sealing tapes. Shearbolt and compression style terminals and pin connectors are available to provide reliable connection to a variety of conductors.

CST components have full trace ability to raw materials and are in compliance with the following international standards: IEEE-48, CENELEC HD 629.1.S2 (includes IEC, BS, VDE and other international specifications).